A manual pad printer is a versatile printing technique used to transfer images onto various surfaces using a silicone pad․ It offers precision, adaptability, and customization for diverse applications․

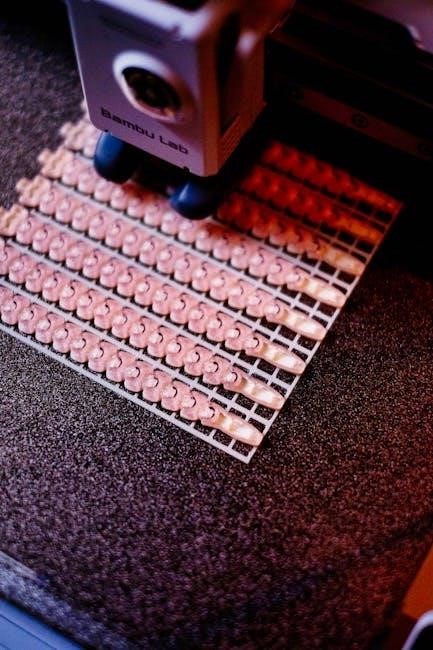

What is a Manual Pad Printer?

A manual pad printer is a device used to transfer images or text onto surfaces using a silicone pad․ It is commonly employed in various industries for printing logos, labels, and designs on products․ The printer operates by transferring ink from an etched plate to the pad, which then stamps the image onto the target material․ Known for its simplicity and flexibility, manual pad printers are often used in small to medium-scale operations due to their cost-effectiveness and ease of use․ They are particularly suitable for printing on curved or irregular surfaces, making them ideal for applications in plastics, electronics, and medical devices․

History and Evolution

The manual pad printer traces its origins to the mid-20th century, evolving from basic stamping tools to sophisticated devices with silicone pads and automated systems․

Development of Pad Printing Technology

The development of pad printing technology began with basic mechanical systems, focusing on transferring images using silicone pads․ Early systems were limited in precision and material compatibility․ Advances in silicone chemistry improved pad durability and ink transfer quality․ The 1980s saw the introduction of automated systems, enhancing efficiency and consistency․ Modern innovations include digital controls, UV-curable inks, and integration with IoT for real-time monitoring․ These advancements have expanded pad printing’s applications across industries, enabling high-speed, high-quality printing on diverse surfaces․ The technology continues to evolve, addressing challenges like sustainability and customization demands․

Working Principles

A manual pad printer transfers images using a silicone pad that picks up ink from an etched plate and applies it to a substrate, ensuring precise ink placement․

Overview of the Printing Process

The manual pad printing process involves several key steps to achieve precise image transfer․ First, the printing plate is prepared with the desired design etched into its surface․ Ink is then applied to the plate, filling the etched areas․ A silicone pad is pressed onto the plate, picking up the ink․ The pad is then transferred to the substrate, where the ink is deposited, creating the printed image․ This process is repeated for each color or layer required․ The pad’s flexibility allows printing on curved or uneven surfaces, making it ideal for diverse materials․ Proper alignment and pressure ensure consistent results, while manual operation offers control over print quality and registration․

Ink Transfer and Curing Process

The ink transfer process in manual pad printing begins with the silicone pad picking up ink from the etched printing plate․ The pad then transfers the ink to the substrate, ensuring precise deposition․ After transfer, the curing process commences, which involves drying and setting the ink․ Curing methods vary, including air drying, heat application, or UV exposure, depending on ink type․ Proper curing ensures durability and adhesion, preventing smudging or peeling․ Factors like temperature, exposure time, and ink formulation are critical for optimal results․ Correct curing is essential for achieving high-quality, long-lasting prints, making it a crucial step in the manual pad printing process․

Role of the Pad in Printing

The silicone pad plays a critical role in manual pad printing, serving as the intermediary between the printing plate and the substrate․ Its flexibility allows it to conform to irregular surfaces, ensuring precise ink transfer․ The pad picks up ink from the etched areas of the plate and transfers it to the target material, maintaining image integrity․ Its elastic properties enable consistent printing on curved, flat, or uneven surfaces․ Proper pad selection, including durometer hardness, is essential for optimal results․ Regular maintenance of the pad, such as cleaning and storing, ensures longevity and consistent print quality, making it a vital component in the manual pad printing process․

Key Components

The essential elements of a manual pad printer include the print pad, ink cup, printing plate, and machine frame, each playing a vital role in the printing process․

The Print Pad

The print pad, a critical component, is typically made of silicone, offering durability and flexibility․ It varies in hardness (shore durometer) to suit different surfaces and image sizes․ Softer pads are ideal for curved or irregular surfaces, while firmer pads are better for fine details and flat areas․ The pad’s ability to pick up ink from the etched plate and transfer it to the substrate ensures precise image reproduction․ Proper pad maintenance, including cleaning and storing, is essential for consistent printing quality․ Over time, the pad may wear out, requiring replacement to maintain optimal performance and clarity in printed results․

Ink Cup and Ink Supply System

The ink cup and ink supply system are essential for delivering ink to the printing plate․ The ink cup holds the ink, ensuring consistent availability․ The Doctor Blade scrapes excess ink, maintaining precise levels․ This system ensures smooth ink transfer to the pad․ Proper ink viscosity and regulation are crucial for clear prints․ Regular maintenance, like cleaning and refilling, prevents clogs and ensures optimal performance․ The ink cup’s design allows easy adjustment, adapting to different printing needs․ This system’s efficiency directly impacts print quality and production speed in manual pad printing processes․

Printing Plate

The printing plate in a manual pad printer holds the image to be transferred․ Made from materials like steel or polymer, it is durable and precise․ The image is etched onto the plate, ensuring high-quality prints․ Proper plate preparation is crucial for clear transfers․ The plate’s thickness and material affect ink transfer and print consistency․ Regular cleaning and maintenance prevent ink buildup and ensure longevity․ The printing plate is a key component, directly influencing print quality and accuracy in manual pad printing processes․

Machine Frame and Mechanical Parts

The machine frame and mechanical parts of a manual pad printer provide stability and precision during printing․ Constructed from durable materials like metal, the frame ensures longevity and supports smooth operation․ Mechanical components, including levers or cranks, enable manual control, allowing users to adjust pressure and alignment․ These parts are designed for ease of use and minimal maintenance, reducing downtime․ The frame’s robust design accommodates various print pad sizes, making it versatile for different applications․ Regular lubrication of moving parts ensures optimal performance and extends the machine’s lifespan, making it a reliable tool for consistent, high-quality printing results․

Applications

Manual pad printers are widely used in plastics, electronics, medical devices, and automotive industries for printing on irregular surfaces, offering versatility and precision․

Plastics and Packaging Industry

Manual pad printers are extensively used in the plastics and packaging industry for printing logos, branding, and regulatory information on plastic products․ Their ability to print on curved, uneven, or complex shapes makes them ideal for items like bottles, containers, and packaging materials․ The silicone pad ensures precise ink transfer, maintaining high-quality images even on non-flat surfaces․ This method is particularly effective for high-volume production, where consistent and durable printing is essential․ Additionally, manual pad printers support the use of UV-curable inks, which offer superior adhesion and resistance to wear, making them a reliable choice for the plastics and packaging sector․

Electronics Manufacturing

In the electronics manufacturing sector, manual pad printers are widely utilized for printing on small, intricate components such as resistors, capacitors, and circuit boards․ The precision of pad printing ensures consistent and high-quality branding or marking, even on curved or uneven surfaces․ This method is particularly advantageous for printing serial numbers, logos, or technical specifications on electronic devices․ The use of UV-curable inks enables rapid drying and durability, making it suitable for high-volume production․ However, the process requires meticulous setup and alignment to accommodate the tiny dimensions of electronic components․ Despite these challenges, manual pad printers remain a reliable solution for achieving detailed, long-lasting prints in electronics manufacturing․

Medical Device Industry

Manual pad printers play a crucial role in the medical device industry for marking and branding purposes․ They are used to print logos, serial numbers, and regulatory information on medical instruments, implants, and disposable devices․ The ability to print on curved or irregular surfaces makes pad printing ideal for items like syringes, catheters, and implantable devices․ Biocompatible inks are often used to ensure safety and compliance with medical regulations․ The precision and reliability of manual pad printers are essential for maintaining the high standards required in healthcare; This method is particularly valued for its ability to produce high-resolution prints on small, complex components, ensuring traceability and compliance in medical manufacturing․

Automotive Sector

Manual pad printers are widely utilized in the automotive sector for printing logos, serial numbers, and safety information on vehicle components․ Their ability to print on curved or irregular surfaces makes them ideal for parts like dashboards, control panels, and engine components․ UV-curable inks are commonly used to ensure durability and resistance to harsh environments․ This method is particularly effective for marking small batches or custom orders, ensuring precise and consistent results․ Pad printing plays a crucial role in maintaining brand consistency and regulatory compliance in the automotive industry, making it a reliable choice for manufacturers seeking high-quality, durable prints on complex surfaces․

Operation and Maintenance

Manual pad printers require regular maintenance to ensure optimal performance․ Cleaning the pad and ink system, aligning the printing plate, and checking mechanical parts are essential tasks․

Setting Up the Machine

Setting up a manual pad printer involves several key steps to ensure proper functionality․ First, the machine must be placed on a stable, flat surface to prevent vibration․ Next, the printing plate is securely installed, ensuring it is aligned with the pad․ The ink cup is then filled and positioned correctly, with the ink supply system adjusted for consistent flow․ The silicone pad is attached, and its hardness (durometer) is checked to match the printing requirements․ Finally, a test print is performed to verify alignment, ink transfer, and overall performance․ Proper setup is crucial for achieving high-quality prints and extending the machine’s lifespan․

Printing Process Steps

The printing process with a manual pad printer involves several precise steps․ First, the pad is lowered onto the printing plate, where it absorbs the ink․ The pad is then pressed against the target surface, transferring the image․ Adjustments are made to ensure proper alignment and pressure․ Multiple colors require sequential printing, with drying time between layers․ Ink levels and pad condition are monitored to maintain quality․ Post-printing steps include cleaning the pad and plate to prevent ink buildup․ Regular checks ensure consistent results․ This step-by-step approach ensures high-quality, precise prints, making manual pad printing a reliable method for various applications․

Maintenance and Cleaning

Regular maintenance and cleaning are crucial for ensuring the longevity and optimal performance of a manual pad printer․ The print pad, ink cup, and printing plate should be cleaned after each use to prevent ink buildup․ Use recommended solvents to remove dried ink, as improper cleaning can damage the pad․ After cleaning, allow all components to air dry completely to avoid moisture interference․ Lubricate moving parts periodically to ensure smooth operation․ Always follow manufacturer guidelines for cleaning solutions and techniques․ Regular upkeep prevents clogging and extends the life of the printer, ensuring consistent print quality and reliability in various printing applications․

Advantages and Limitations

Manual pad printing offers adaptability for curved surfaces and high precision but requires skilled operators and is less efficient for large-scale production, limiting its scalability․

Advantages of Manual Pad Printing

Manual pad printing is highly adaptable, enabling precise printing on curved, uneven, and complex surfaces․ It offers excellent image fidelity, making it ideal for intricate designs․ The process is cost-effective for small batches and customization, reducing initial investment costs․ Additionally, it allows for quick setup and minimal material waste, making it eco-friendly․ The manual operation ensures low energy consumption, appealing to environmentally conscious businesses․ Furthermore, it supports a wide range of inks and materials, offering flexibility in various industries․ Overall, manual pad printing balances quality, efficiency, and sustainability, making it a preferred choice for specific applications․

Limitations and Challenges

Manual pad printing has several limitations, including labor-intensive operation, requiring skilled operators for consistent quality․ It is less efficient for large-scale production due to its slow, manual nature․ Pad wear and tear necessitate frequent replacements, increasing maintenance costs․ Achieving high precision on intricate designs can be challenging․ Additionally, the process is unsuitable for very large or complex images․ Cleaning and ink management also demand regular attention․ While it excels in niche applications, manual pad printing struggles with high-volume demands and precise detailing, making it less ideal for industries requiring rapid, high-precision output․

Troubleshooting

Troubleshooting manual pad printers often involves addressing ink smudging, misregistration, and pad wear․ Regular cleaning, alignment checks, and pad replacements can resolve these common issues effectively․

Common Ink-Related Issues

Manual pad printing often encounters ink-related challenges, such as smudging, misregistration, and adhesion problems․ Ink smudging occurs when the pad lifts excess ink, causing blurry images․ Misregistration happens when the pad misaligns with the substrate, leading to distorted prints; Adhesion issues arise if the ink fails to bond properly with the material, often due to surface preparation or ink formula incompatibility․ Additionally, ink viscosity and drying times can affect print quality․ Environmental factors like temperature and humidity may alter ink consistency, requiring adjustments․ Proper ink management, including accurate viscosity control and surface treatment, is essential to mitigate these issues and ensure sharp, consistent results․

Registration and Alignment Problems

Registration and alignment issues are common challenges in manual pad printing, often leading to misaligned designs․ These problems occur when the pad, printing plate, or substrate are not properly aligned, resulting in distorted or offset prints․ Improper machine setup, worn-out pads, or uneven substrate surfaces can exacerbate these issues․ Additionally, operator error, such as incorrect pad pressure or angled strikes, can disrupt alignment․ To address this, precise calibration of the machine and regular maintenance of parts are crucial․ Using alignment guides and ensuring the substrate is securely positioned can also help minimize errors; Proper training and attention to detail are essential to achieve consistent, high-quality results․

Pad Wear and Tear

Pad wear and tear is a common issue in manual pad printing, affecting print quality over time․ The silicone pad, essential for transferring images, can degrade due to frequent use, harsh inks, or improper cleaning․ Signs of wear include cracks, uneven surfaces, or loss of shape, leading to distorted prints․ Factors like ink type, pad hardness, and printing frequency contribute to wear․ Regular inspection and maintenance, such as cleaning and storing pads properly, can extend their lifespan․ Replacing worn pads when necessary ensures consistent results․ Proper care and handling are vital to maintaining optimal printing performance and minimizing downtime․

Future Trends

Future trends in manual pad printing focus on automation, digital interfaces, and sustainable practices to enhance efficiency and customization while reducing environmental impact․

Advancements in Pad Printing Technology

Recent advancements in pad printing technology include the integration of digital control systems, enabling precise ink transfer and consistent print quality․ Innovations in silicone pad durability and ink formulations have expanded the range of printable materials․ Automated systems now offer real-time monitoring and adjustment, reducing human error․ Additionally, eco-friendly inks and energy-efficient machines are gaining traction, aligning with sustainability goals․ These improvements enhance the versatility and efficiency of manual pad printers, making them suitable for high-volume and intricate applications across industries․ Such technological strides ensure pad printing remains a competitive and adaptable solution in modern manufacturing and printing sectors․